VP2000 inline

High-Performance inline systems for large series

Features

The concept

Full inline integration and no need for workpiece carriers, this is the focus of ASSCON´s vapor phase inline soldering systems. The simple transfer and takeover of PCBs via pin chains characterize this type of inline system. Electrically width-adjustable transport systems allow fast and uncomplicated adaptation to changing products and thus offer the flexibility required in today’s modern electronics production. The integration into inline control computers is also possible. Full automation combined with the highest quality in the process is the guiding principle here.

Flexible inline production - the three models.

Maximum solder length (Loading 2 to 8 PCBs)

125 - 600 mm (see details)

Option Longboard

PCBs up to 1,200 mm length

Maximum transport width

520 mm

Maximum solder height

60 mm

Maximum component height below

20 mm

Power supply

400V/3/N/PE- 50 Hz/60 Hz

Connection load

11,6 kW

Average energy consumption

3,4 kWh

Time to operation

ca. 30-45 min

possible loading according to solder length

Loading 2 PCBs: up to 600 mm

Loading 3 PCBs: up to 390 mm

Loading 4 PCBs: up to 285 mm

Loading 6 PCBs: up to 175 mm

Loading 8 PCBs: up to 125 mm

Maximum solder length (Loading 2 to 8 PCBs)

165 to 620 mm (see details)

Option Longboard

PCBs up to 1,500 mm length

Maximum transport width

620 mm

Maximum solder height

60 mm

Maximum component height below

20 mm

Power supply

400V/3/N/PE- 50 Hz/60 Hz

Connection load

15,9 kW

Average energy consumption

4,8 kWh

Time to operation

ca. 30-45 min

possible loading according to solder length

Loading 2 PCBs: up to 620 mm

Loading 3 PCBs: up to 510 mm

Loading 4 PCBs: up to 370 mm

Loading 6 PCBs: up to 235 mm

Loading 8 PCBs: up to 165 mm

Maximum solder length (Loading 2 to 8 PCBs)

165 to 620 mm (see details)

-

-

Maximum transport width

2 x 275 mm

Maximum solder height

60 mm

Maximum component height below

20 mm

Power supply

400V/3/N/PE- 50 Hz/60 Hz

Connection load

15,9 kW

Average energy consumption

4,4 kWh

Time to operation

ca. 30-45 min

possible loading according to solder length

Loading 4 PCBs: up to 620 mm

Loading 6 PCBs: up to 510 mm

Loading 8 PCBs: up to 370 mm

Loading 12 PCBs: up to 235 mm

Loading 16 PCBs: up to 165 mm

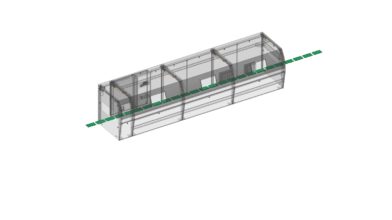

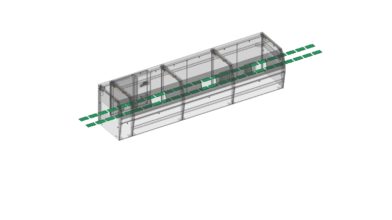

Pictures VP2000-210

Integration of an Asscon inline system in an entire production line