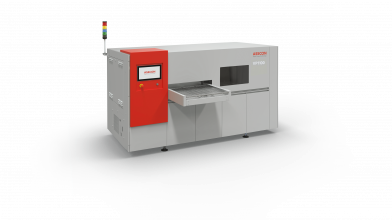

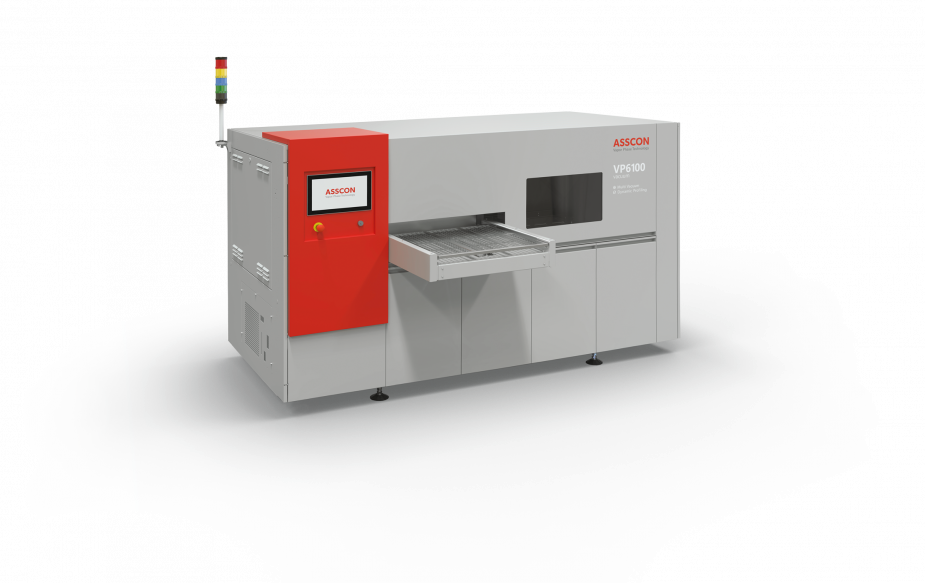

VP1100 / VP6100 vacuum

Stand-Alone system for flexible production

Features

The concept

Maximum flexibility and optimum soldering quality are essential features of ASSCON stand-alone vapor phase soldering systems. By using workpiece carriers, these systems are excellently suited for small and large production quantities as well as for any design and size of assemblies. Due to their compact design, the multi-chamber systems can find a place in almost any production. The conception as batch systems allows an island production. In this way, the system can be fed from a wide variety of production stations.

Details

Workpiece carrier format

610 x 610 mm

Maximum solder height

60 mm

Maximum transport clearance

100 mm

Power Supply

400 V / 3 / N / PE 50 Hz

Connection Load

9,2 kW

Average energy consumption

3,3 kWh

Oxidation-free preheating and soldering process

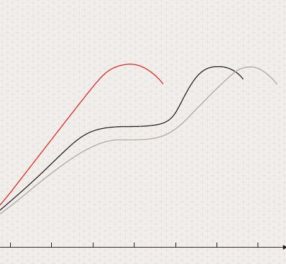

Continuously adjustable temperature gradient through sensor-based profiling

Optional: Dynamic Profiling and Dynamic Profiling PLUS+

Can be used in 24/7 series operation

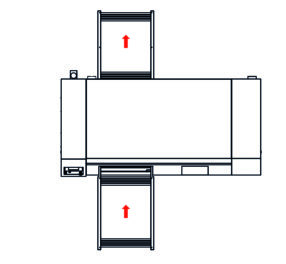

2-Chamber-System

Low medium consumption

Internal memory of up to 500 soldering programs

Cost-effective soldering system for the highest technological requirements

Workpiece carrier format

600 x 600 mm

Maximum solder height

60 mm

Maximum transport clearance

100 mm

Power Supply

400 V / 3 / N / PE 50 Hz

Connection Load

13,4 kW

Average energy consumption

3,7 kW

End vacuum (pump)

0,5 mbar

Vacuum module with Multi Vacuum technology

Dynamic Profiling as standard

VP6100 vapor phase soldering system with Multi Vacuum